-

4.9 Stars ⭐⭐⭐⭐⭐ 448 Google Reviews

-

Posts

301 -

Joined

-

Last visited

-

Days Won

2 -

Country

United Arab Emirates -

Carnity Points

235 [ Donate ]

Content Type

Profiles

Forums

Advice

Business Listing

Car Deals

Recall

OBD II Car Diagnostics

Guest lead capture

STORE

Events

Gallery

Blogs

Everything posted by Alex Raptor

-

I should add as well, that by having the air tank I can run air tools as well, the idea being that I can run a high lift air jack to assist in pop outs on one compressor whilst having the other one with a single hose and chuck to inflate the offending tire, also there is another pipe hidden away that joins the two air tanks with a valve so if one compressor fails I can open the valve and still use the system on a single compressor.

-

Welcome to my world, I lay awake at night optimising airflows and trying to work out a way to stay in the cab whilst this is all going on, whilst worrying about how to fold the hose and stop it taking over the truck, with such a long beast as the raptor, it needs a 5 metre run from the tailgate to the front, what about the tire chucks how do they stay on, what is the length of the valve and the flow difference between 3/8 pipe and 1/4, the list is endless and mind boggling. For some reason my tires have always been at 40 psi for the road. But now I think I have the solution. I haven't completed it yet, but I'm splitting the truck into left and right. There is a dual ARB on either side of the truck bed with a 1 gallon air tank and a pipe to an air manifold. That manifold has a pressure gauge if needed and a US standard (ARB) air socket, and a 1/2 inch solenoid valve (closed when no current). The valve is connected to a switch in the cab one for each side, along with a switch for each compressor. I arrive I connect one hose to each side and a push on "closed" (no air when off) chuck on each valve I return the the cab and I switch on each solenoid and monitor the air pressure via TPMS. because it is connected to two tires I can effectively balance the front an back pressures if one deflates quicker than the other. Once finished I remove the hose from each side and place each hose in a mesh bag. When I want to inflate, I attached the hose and chucks and turn on the compressors, using the TPMS to reach the desired pressure. By having two ARB dual compressors it will reduce the time by half to inflate, currently 20 mins will now be around 12 mins. Raptor tires are huge. Might be overkill for some people, but I have really enjoyed making this system and learning about airflow in parallel and in series and manifolds etc. I have seen some trucks in the USA that have four individual pressure switches and dump valves and a plumbed network of pipes with small whips to the valves, this allows them to set pressures manually for each tire for inflation and deflation, a central pressure switch that effectively is controlling four tires I have tested and found it not to work effectively. TPMS in my experience will have one tire every 15 inflations that fails to register but by holding a magnet close to the tire valve you can force a reading to update, the TPMS (as I understand) works by sending a signal every few times it rotates and meets a magnetic field somewhere in the wheel well. Now if only I can find a hydraulic arm to put my flag on and off................

-

D292833A-4897-4A39-867E-EB8D949FBD44.jpg

Alex Raptor commented on Batuhan Kulac's gallery image in Fewbie Plus - Al Qudra to Lisaili - Dubai - 8 May 2021

-

D292833A-4897-4A39-867E-EB8D949FBD44.jpg

Alex Raptor commented on Batuhan Kulac's gallery image in Fewbie Plus - Al Qudra to Lisaili - Dubai - 8 May 2021

-

5BAD9F67-DE7D-4026-98C2-F80BDCD0F394.jpg

Alex Raptor commented on Batuhan Kulac's gallery image in Fewbie Plus - Al Qudra to Lisaili - Dubai - 8 May 2021

-

Today was a perfect day ( last one I promise), open flowing drive, not too hot, a real mixed convoy, now I see the benefit of mixed convoys, I really enjoy helping out and learning and if possible sharing some knowledge, I learnt today all about Mitsubishi relays and how to get the most out of the Pajero before resorting to external forces. Invaluable. Our good friends Momentum and Commitment were also coming out to play and by the closing stages were in full effect and performing well. We have to remember that what we do is not necessarily natural, our motto of not fighting gravity can be counter intuitive, but once grasped opens the door to improving ones skills. I for one will be signing up for lots more newbies and fewbies, its fun and rewarding. This is what we came for (sorry I lied, Rihanna I think). See you all again soon.

-

Dodi Syahdar has been promoted to Intermediate level

Alex Raptor replied to Gaurav's topic in Off-Road Club's Announcements

Great news @Dodi Syahdar well done, another Raptor in the inters. -

@Shehab Alawadhiyou’ve got me started, The F150 I think, is the world's most popular truck, selling over 2,000 trucks per day, the suspension options are limitless. My issue is warranty, we don't have any real legal precedent here in the UAE on proving whether a component change was directly responsible for a failure on something on the truck, whereas in the USA, the onus is on the dealer and brand to prove that your modification caused the failure (Magnuson-Moss Warranty Act). I think you have the same 3-5 year warranty I have on the Raptor, and I have been told that any changes to the suspension will effectively cancel any warranty for suspension, axles, drivetrain and engine. A 2 inch lift on the F150 or Raptor would be great, a bit more travel offered by the FOX kits would be great, but I don't know if it is worth it until our warranties expire. Also some suspension upgrades require rebuilds at certain intervals, thus adding to the cost. Just FYI, I looked into Fox 3.0 suspension, deever springs and hydraulic bump stops with upper control arms and it was looking close to 60,000 AED. I don't see myself partaking in any desert activity that would require that sort of setup with my daily driver. From my research our leaf springs will eventually flatten out and will need replacing, the shocks will need to be replaced as well, hopefully 5,000 km before the expiry of the warranty!!! You have already addressed your approach angle, which I am now looking at as well both front and rear, I don't think that can be seen as a warranty stopper.

-

Watteau has been promoted to Intermediate level

Alex Raptor replied to Gaurav's topic in Off-Road Club's Announcements

Very kind words @Wrangeld Richard Thank you. Will keep on pushing and learning. Bake off in the desert is next. See you soon. Thanks again -

Watteau has been promoted to Intermediate level

Alex Raptor replied to Gaurav's topic in Off-Road Club's Announcements

Thanks @Gaurav, thanks to all the Leaders and my fellow drivers for their advice and input, onwards and upwards. See you all soon. -

Arman has been promoted to Intermediate level

Alex Raptor replied to Gaurav's topic in Off-Road Club's Announcements

@Arman whoop whoop, you got it man, well done and exceptionally well deserved, see you soon -

What a team, we were struck be adversity and its was handled with military precision, great skills and perfect execution @Kailas @Islam Soliman @Jeandre Bezuidenhout and to add @Shehab Alawadhi for his excellent execution of a difficult tow, it’s a great area to explore at night and lots of lessons in there, really enjoyed it, thanks again guys. Did anyone else get stopped at last exit?

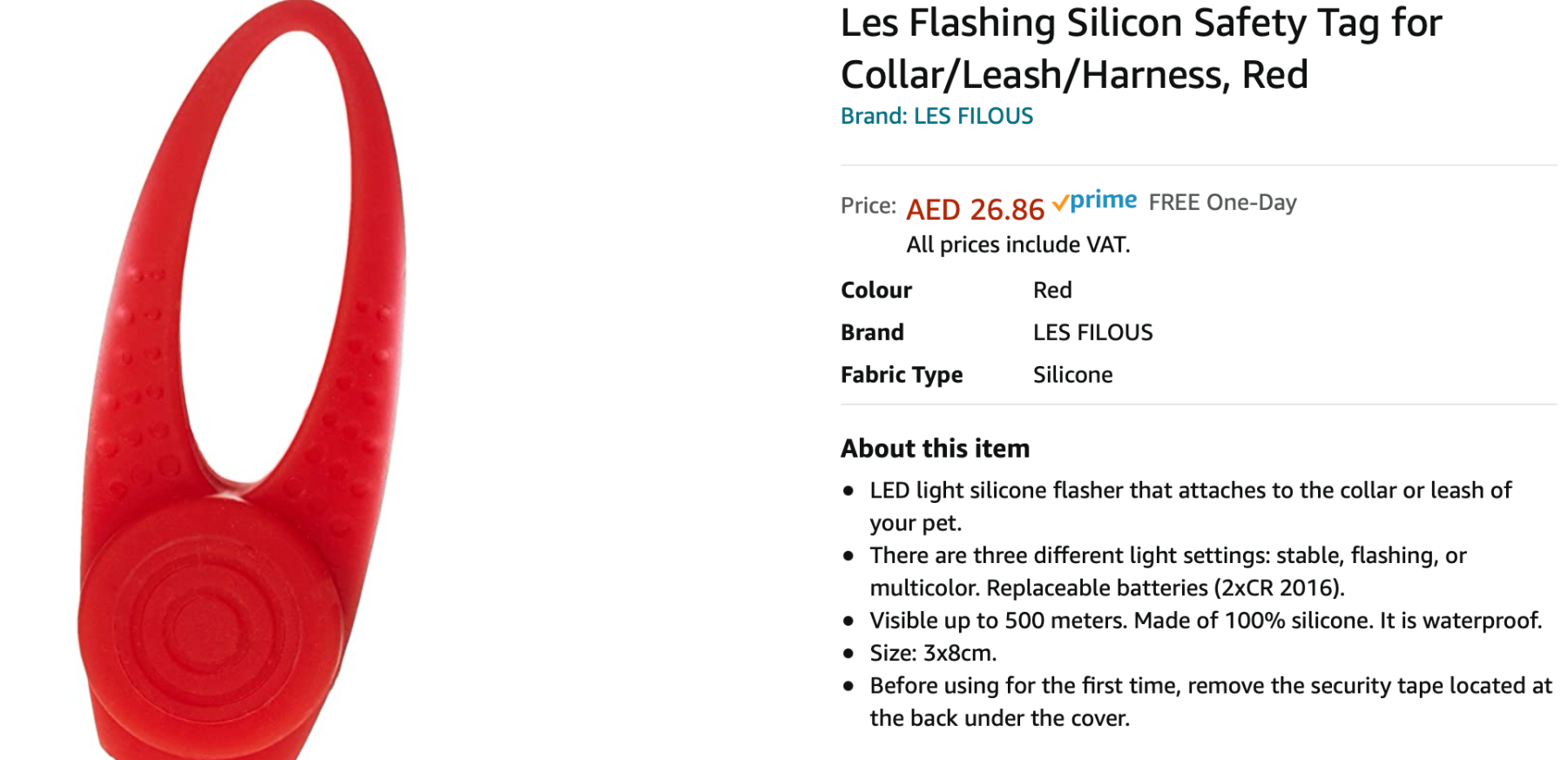

-

thanks @Luca Palanca Falsini and @Niki Patel for a tremendous drive this morning, we thoroughly enjoyed it, very grateful for the help and advice on my first pop out. I have just returned from the tire shop less 1kg of sand from the inside of my tire and ready to go, it lost 7 psi on the way home with no noticeable wobble, but was amazed how much came out. Time for a pop out kit bag with water spray, single inflate hose and blower. See you all soon.